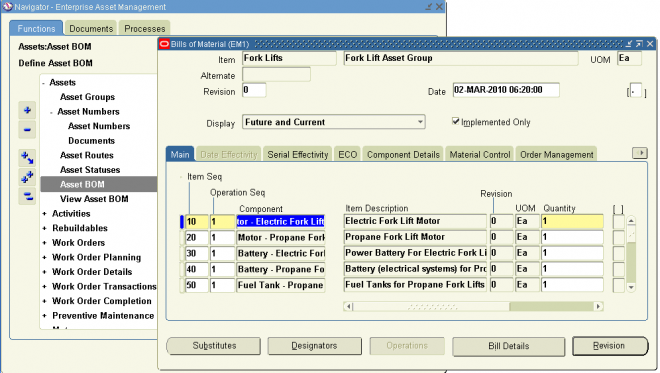

Setting Up Asset (Group) Bills of Material

You can identify and select the required items that make up an asset. A bill of material (BOM) can be used to list all items and components that make up a particular asset, and can be defined for each Maintained Group. The items defined

on an asset BOM are standard inventory components.

Note: Even if you are not using Project Manufacturing applications, Project Parameters must be defined for your eAM

enabled organization to successfully create Asset Groups. This is required because an Asset BOM is of type Model/Unit Effective and this BOM type is currently allowed only if PJM organization parameters are set up for the eAM enabled organization to which the Asset Group has been assigned. To define Project Parameters, open the Project Parameters window using Project Manufacturing Super User responsibility and without entering any data in the window, save the record.

To set up an Asset BOM:

1. Navigate to the Bills of Material window.

2. Select a Maintained Group from the Item field list of values.

3. Within the Main tabbed region, the Item Sequence and an Operation Sequence will default.

4. Enter the inventory Component to make up the Maintained Number.

5. Enter the Quantity of that component necessary for the asset.

6. Select the Serial Effectivity tabbed region.

7. Select the Maintained Number (Maintained Numbers are always serialized) from the list of values that the inventory items are going to be associated to, in the From and To fields. Only Maintained Numbers associated with the current Maintained Group are available.

If the Component is installed in all Maintained Numbers within the Maintained Group, enter 0 in the From field, and leave the To field blank.

8. Save your work.

auto request material

HI

please tell me how i can setup system that auto request material hasnot been selected by default

regards

razie